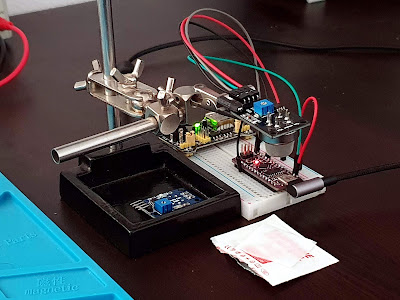

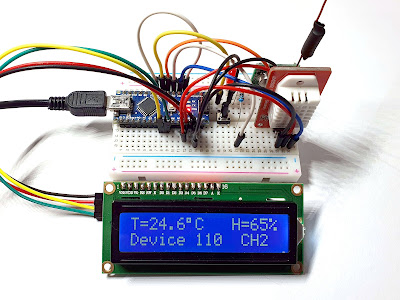

A while ago (to be more specific two years ago) I used software defined radio to capture and decode RF signal from the outdoor unit of a weather station. This allowed me to emulate the protocol with an Arduino and a cheap 433.92 MHz transmitter and send my own data to the indoor station. I can make my own units if the original outdoor unit fails. The outdoor unit uses on-off-keying (OOK) and sends pulse distance modulated bits, explained in detail in the linked post.

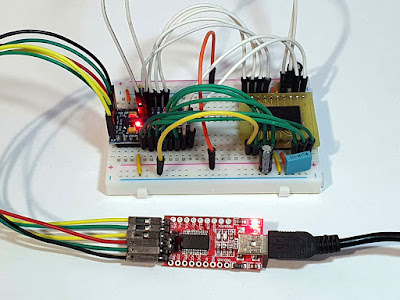

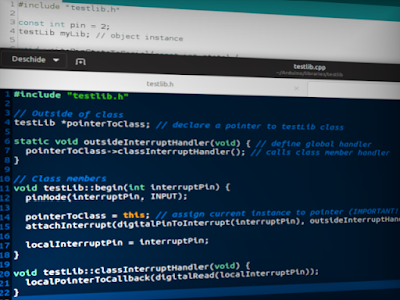

But what about receiving data from outdoor unit(s) with an Arduino? One can add an ESP8266 to capture temperature and humidity and publish data to MQTT, Home Assistant or other IoT servers. Capturing and analyzing pulse timings of a signal was a daunting task for me. However it turned out to be easier than I thought, using an interrupt routine. In this post, I'll explain all the steps required to make a pulse distance modulation (PDM) decoder.